The Process of Making Alligator Shoes

A lot of people usually use some shoes made from alligator skin. But did you ever realize why it is so expensive and the process of how they are actually made?

Today, we will talk about the process of making alligator shoes. If you are going to start the process, of course, you need to think first the design as well as the style of the shoes. This is most important thing to do. Since the alligator skin is so delicate, the designer should also be careful on doing it. That’s why they really have to decide the proper style and design of the shoes.

If the design is already approved then that’s they can already immediately start to make the last of the shoe. Designers carved the last of the shoe by the use of their hands. After carving, the next thing to do is the upper style. It must be formed perfectly.

If you think that the machine is the one which makes the shoes, well you are wrong. The whole process in making the alligator shoes is usually made by the hand.

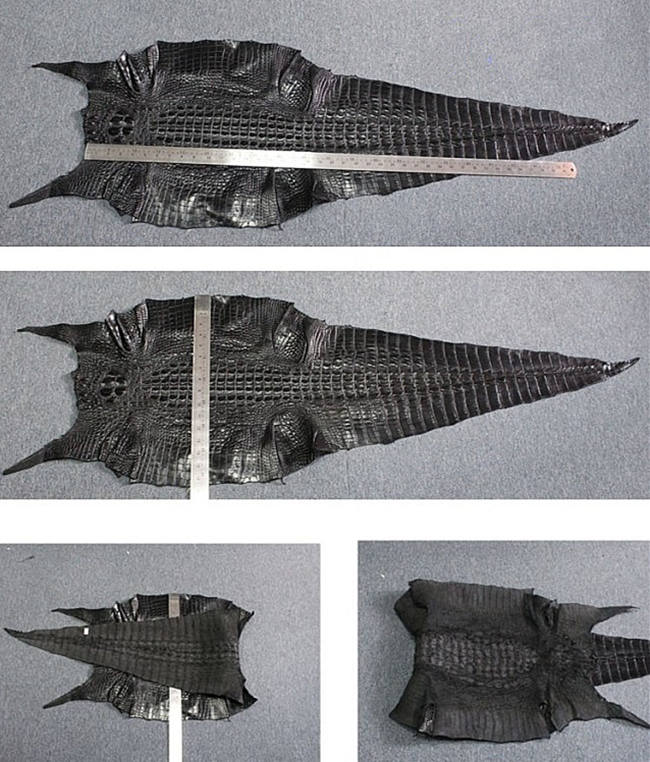

Now we are going begin to take the alligator skins and we will start to cut the pattern into pieces for the various upper sections. If you are going to notice there are scales in the skin of the alligator that’s why always remember to match the scale as well as the size for consistency. If you perfectly do it, you can already make a pair of shoes that exactly match to each other.

In order for the skin to look smoother, it must go through a skiving machine. This is right after the skin are cut into pieces. All the pieces must go through the skiving machine. After all this process, it is now to do the embroidery as well as the decorative holes. If all of these are done, they can already proceed to the process of fashion detailing. But only the artist that has the experience and the skills is allowed to do the fashion detailing. Their job is truly challenging. They need to make it perfect. As much as possible they avoid on committing mistakes since they know how expensive the skin of the alligator is. They make sure that is well done. They also assure that is made from a quality of alligator’s skin because clients can easily identify whether it is 100% made from alligator skin or not.

For the last step, when the upper part of an alligator was already attached to the lining area of the shoe, they will now attach the upper to the mid sole. The artist will do all the process including the process of taking the shoe upper as well as in preparing the sole. If you are going to notice after this, the artist will now begin the grind down the bottom of the upper part. They will do the grinding and hammering done. After this, the bottom of the alligator will now receive the coating by the use of the glue and after the shoe, artist will sew the leather sole as well as the heel.